Tube Fabrication

For nearly 30 years, Fabritex has been a leader in precision tube fabrication. From multi-axis tube bending and fabrication to standard bend radii, and sweeping roll bends and more, Fabritex has the reputation of being the go-to partner of choice across industries.

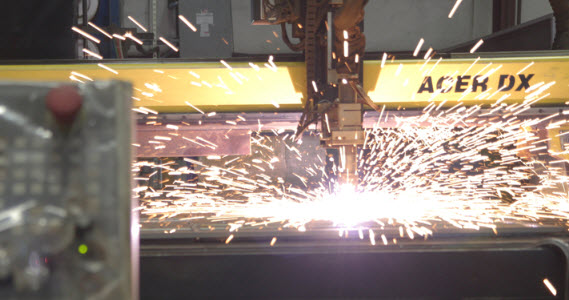

Steel Metal & Plate Fabrication

How important is it that Fabritex has spanned 30 years in the sheet metal and plate fabrication industry?

Outsource Manufacturing

Fabritex meets your outsourcing needs with quality with traceability. When you need to spend more time in assembly and less in fabrication we can meet that need and supply you and your engineers with high-quality parts

Got A Project?

We specialize in Tube, Sheet Metal and Plate fabrication. No job is too small or too large. Contact us today to request a quote!

Fabritex has been doing Metal Fabrication for over 16 years. We specialize in tube, sheet metal and plate fabrication. It’s our goal to be a leader in the metal fabrication industry. With almost 30 years of experience, skilled employees who regularly expand their knowledge, and 110,000 sq. ft. plant containing state-of-the-art equipment, we can take our customers’ projects from concept to completion seamlessly and without unnecessary delays.

Our reputation in the industry is solid – and that’s something that still means a great deal to us, something we strive to maintain. We are a one-stop solution for metal fabrication projects of all sizes and take pride in exceeding our customers’ expectations.

Fabritex is ISO 9001:2008 certified, combining quality with the traceability needed by the clients who have trusted us with their outsource manufacturing needs.

Capabilities

We take a holistic approach to each project for our customers. Our goal is to be a one-stop-shop for our customers. We have engineers who are certified in all 50 states and a suite of advanced software including both Solid Works and CAD/CAM. In addition to our design tools, our full-service metal fabrication shop boasts some of the most precise and efficient equipment for your requirements, including laser cutting equipment and a robotic welder. This means that we are able to produce sheet metal products that exceed your expectations with exceptional service and tight tolerances.

To learn more about our full list of capabilities, click on the button below.